3D printing. Though the technology is still in its infancy, it’s still hard not to be amazed at its capabilities- and builders and investors alike are now dreaming of how 3D printing can cut time and costs on their projects.

Of course, Advanced Modular Space knows a thing or two about efficient building processes- after all, we pride ourselves on our modular building inventory. Building modular means that we fabricate structures in a factory, with precise, assembly-line style production, bypassing all of the additional costs and setbacks that can be involved with traditional construction. Modular buildings are often much more sturdy than traditionally constructed buildings, and buying or leasing one can be done at fractions of the price.

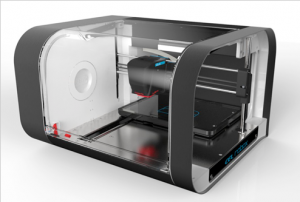

So, when it comes to emerging technologies like 3D printing, Advanced Modular Space keeps close tabs. After all- who wouldn’t like to cut down on costs and time? Unfortunately, the technology is not so sufficiently advanced that it would be profitable (or even feasible) for us to utilize it effectively. 3D printers can only print in a small pool of materials- resins, plastics, and ceramics, and some metals- not enough to cover all of the materials needed for one of our high quality modular buildings. Could you imagine a 3D printer the size of a factory, though, printing out fully functional buildings, ready to be shipped? This technology is right around the corner, and Advanced Modular Space is always keeping an eye on competitive advantages. Food for thought!

Check out our inventory of new and used modular buildings here to find the perfect modular building for your next project.

Leave A Comment